FAQs

-

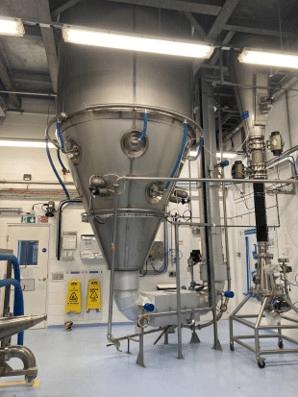

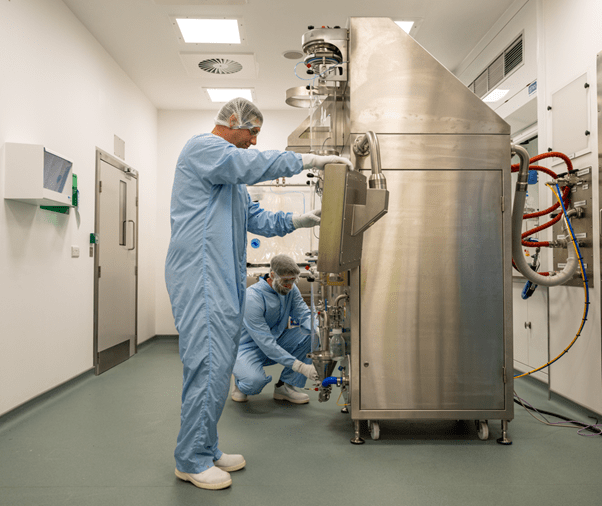

The Spray Drying method has been developed over the last 30-50 years in the food and pharmaceutical industries. It transforms a feed from a fluid state into a dried powder by spraying the feed into a hot drying medium. This versatile process can be used from lab scale all the way up to commercial multi-ton production and, can dry materials while preserving them from degradation.

Spray drying also offers advantages for particle engineering by adjusting particle morphology and characteristic to defined limits to improve a products solubility, bioavailability and flow characteristics.

-

Haverhill has 20 years experience in commercial pharma spray drying.

We have four spray dryers at site measuring from 4.5m to 25 metres in height, one of the largest pharmaceutical spray dryers and continuous manufacturing API plant in the world. Our capabilities include fluid bed drying, tray drying with suitability for GMP activity, aqueous, R&D, small to large scale trials clinical stage I-II and commercial.